PVC Pipe Plant

Vandana Plastic Machineries is one of the leading heavy fabrication and machinery job specialists in Ahmedabad and serving various types of engineering companies for many years. Our main motto is our customer satisfaction and our aim is to have various customers providing better workmanship, quality of product, and after-sales services. We flourished with a good enthusiastic team of professional engineers and staff who are the helping hands for the growth the success of the organization. Further, it is our pleasure to say that the customers have the greatest share in the success of Vandana Plastic Machinery to be the brand name in the market.

In today’s fast-growing competitive market of plastic extrusion machinery, we are recognized as the growth–oriented company that works according to the needs of the plastic manufacturing industry that are techno-driven, and that up-to-date design, configuration, raw materials, and applications for new products call for highly developed technology, experience, and frequent innovation.

What is PVC Pipe?

PVC pipe known as Polyvinyl Chloride pipe is made with the combination of Plastic and vinyl material. These PVC Pipes are durable, hard to damage, and long-lasting. They do not rust, rot, or wear over time. For the same cause, PVC piping is the most commonly utilized pipe in water systems, underground wiring, and sewer lines. Having the unique ability the PVC pipe withstands extreme movement and bending and is also increasingly used in earthquake-prone areas. Further features like the smooth surface of pipes are also good and resistant to bacterial contamination. As a result, many water companies rely on PVC pipes in their systems to keep them free of contamination.

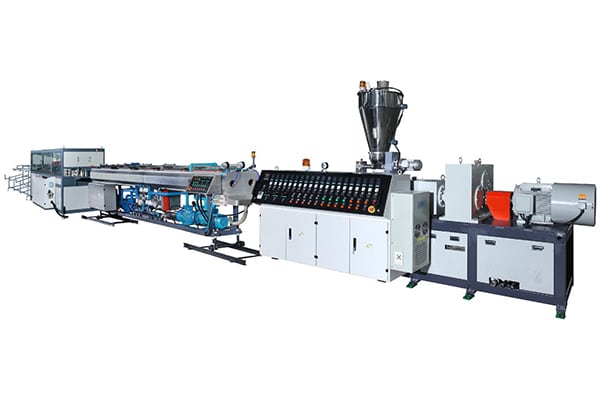

What is PVC Pipe Plant?

The unbending Single Screw Extruder with equipment for producing the PVC pipe, rod and section is known as PVC Pipe Plant. The line that consists of a single screw extruder fitted with electric motor, gear box, belts, pulley and many more spare parts. We are a remarkable organization enthusiastically occupied in offering wide gamut of PVC Pipe Plant. Our offered products are well designed and make sure for long lasting services. We have an all around prepared infrastructural unit that comprises of a few propelled innovation based machines that empower institutionalized generation.

Additionally, our generation unit covers a tremendous region and is uniquely intended for assembling a subjective scope of items in mass amounts. As we lay incredible accentuation on the nature of our items, a strict quality strategy is taken after our quality examiners to guarantee that each item experiences thorough keeping an eye on different parameters and specialized angles to keep up impeccable quality. Alongside this, our solid and composed inventory network framework encourages us to convey items inside the guaranteed time period at the customers’ end.

Manufacturing Process of PVC Pipe Plant

It is well-known that PVC pipe Plant Manufacturers in india is one of the most widely used polymers in the world. Having adaptable nature, the PVC is utilized widely over a wide scope of mechanical, specialized and ordinary applications incorporating boundless use in building, transport, bundling, electrical/electronic and medicinal services applications. PVC is an exceptionally sturdy and enduring material which can be utilized as a part of an assortment of utilizations, unbending or adaptable, white or dark and an extensive variety of hues in the middle.

The fundamental raw materials for PVC are derived from salt and oil. The electrolysis of salt water produces chlorine, which is joined with ethylene to frame vinyl chloride monomer. The particles of VCM are polymerized to shape PVC pitch, to which fitting added substances are consolidated to make an altered PVC compound. The offered PVC takes less non-inexhaustible non-renewable energy source to make than some other ware plastic in light of the fact that not at all like different thermoplastics which are completely gotten from oil, PVC is fabricated from two beginning materials. 57 % of the sub-atomic weight got from basic salt and 43% got from hydrocarbon feedstock that is progressively ethylene from sugar edit is likewise being utilized for PVC creation as a contrasting option to ethylene from oil or gaseous petrol.

While PVC is most every now and again produced using salt and oil, in a few locales of the world PVC is made without utilizing oil feedstock by any stretch of the imagination. PVC is subsequently far less oil-subordinate than different thermoplastics. It is additionally exceptionally tough and vitality productive over a scope of uses, which makes for a to a great degree compelling utilization of raw materials.

PVC Pipe Plant Cost

We are a highly well-known organization engrossed in developing best-in-class PVC Pipe Plants. With our rich industrial experience and expertise, we are engaged in offering the high demand product of the clients. These offered plants are identical in efficiency and are trusted extensively for their cost-saving operations. Our offered plants are furnished with driving quality extrusion lines and cutting-edge vacuum pumps. These plants are produced from industry-affirmed segments and can be requested from us in the application of particular necessities at an ostensible cost. The PVC Pipe Plant we offer is all-around planned and guarantees enduring administration. In addition, these are generally utilized as a part of business and also mechanical ranges because of their solidness.

PVC Pipe Extruder

We are considered to be the foremost organization involved in manufacturing and offering supreme quality PVC Pipe Extruder, which is a versatile model in which you can find great functionality with everything the client accepts. We are manufacturing the machines robustly with the support of quality purchased components as well as constituents. As we are fabricating the PVC Pipe Extruder, and PVC Pipe Extrusion Line on the basis of innovative proficiency and deliver the best performance in a very dependable approach. Our offered machines have plentiful clear processing aspects.

PVC Pipe Machinery

We are included among the reckoned names in the industry, offering a broad scope of PVC Pipe Machinery that is refreshing among the customers for ideal quality and dimensional precision. Be familiar with the current market require, we have built up the most recent specialized pleasantries to offer financially savvy and well performing arrangement of PVC pipe machinery. We offer our hardware with unimportant dismissal rate. It is planned with ‘miscreant’ demonstrating framework and created with splendid checking and investigation approach. The principle point of higher efficiency is accomplished through powerful development and current control framework. It is given productive cooling framework for screw and barrel. The counter wears security of nitride surfaces give the machine long administration life. These surfaces are produced using tungsten carbide and chrome.

Why Choose Vandana Plastic Machineries?

- Unrivaled Quality products as per international standards

- Most Competitive Prices to let you compete in the metal markets.

- Opportune Delivery which should empower you to meet your creation targets

- Client Focused and Growth Oriented Management

- Quick Communication

- On-Going Research and Development to improve our item quality and volumes

- Consumer loyalty is our need

- Constantly redesign Machinery and Equipments to stay aware of innovative advances

SERVICE & SUPPORT

Industries We Serve

Quality Assurance & Control

Application Of PVC Pipe